Outriggers and Lowboy Trailers Guide

Transporting heavy equipment is a critical task in industries such as construction, mining, and agriculture. One essential component that ensures safety and stability during transportation is the outrigger on a lowboy trailer. Outriggers play a pivotal role in enhancing the safety and stability of heavy equipment transport, making them indispensable for trucking professionals. In this guide, we will explore how outriggers improve transportation safety, the key factors to consider when selecting outriggers, the importance of proper use and maintenance, common challenges and solutions, and expert recommendations for customizing outriggers to meet specific needs. By the end of this article, you will have a thorough understanding of how to effectively use outriggers to optimize your heavy equipment transport operations.

Outline:

- How Do Outriggers on a Lowboy Trailer Improve the Safety and Stability of Heavy Equipment Transportation?

- What Are the Key Factors to Consider When Selecting the Right Type of Outriggers for Your Lowboy Trailer In the Trucking Industry?

- How Can Proper Use and Maintenance of Outriggers on a Lowboy Trailer Prolong the Lifespan of Your Heavy Equipment and Reduce Transportation Cost?

- What Are Some Common Challenges and Solutions When It Comes to Deploying Outriggers on a Lowboy Trailer During Heavy Equipment Transportation?

- How Do Industry Experts Recommend Customizing Outriggers on a Lowboy Trailer to Meet Specific Trucking and Transportation Needs for Various Types of Heavy Equipment?

How Do Outriggers on a Lowboy Trailer Improve the Safety and Stability of Heavy Equipment Transportation?

- Reduced tipping risk: The wider base provided by outriggers helps prevent the shipment from tipping over during transport. This is especially crucial when making turns, navigating uneven terrain, or encountering sudden movements or bumps on the road. Imagine a wider stance for better balance.

- Spreads weight more evenly: Outriggers help distribute the weight of the equipment more evenly across the trailer bed and outriggers themselves. This reduces stress on the trailer frame and axles, improving overall stability and minimizing the risk of trailer damage.

- Accommodates wider equipment: Some heavy equipment, like wide excavators or combines, may not fit entirely on the standard width of a lowboy trailer. Outriggers can be used to create a wider platform that safely supports the overhanging equipment.

- Creates a more stable platform: Outriggers provide a more stable platform for loading and unloading heavy equipment. This minimizes the risk of the equipment tipping or rolling off the trailer during these critical processes.

What Are the Key Factors to Consider When Selecting the Right Type of Outriggers for Your Lowboy Trailer In the Trucking Industry?

When selecting the right outriggers for your lowboy trailer in the trucking industry, there are several key factors to consider to ensure optimal safety, stability, and suitability for your specific hauling needs. Here are some aspects to evaluate:

- Match outrigger capacity to your cargo: The primary function of outriggers is to handle the additional weight and width of your equipment. Choose outriggers with a weight capacity exceeding the maximum weight you plan to transport. This ensures a safety buffer and prevents overloading the outriggers themselves.

- Consider equipment dimensions: The size and width of your equipment will influence the outrigger selection. Wider equipment might necessitate outriggers that extend further outwards to create a sufficient support base.

- Manual vs. Hydraulic: Outriggers come in both manual and hydraulic options. Manual outriggers require physical effort to deploy and retract, while hydraulic outriggers use a hydraulic system for easier operation, especially with heavier trailers. Consider the weight of your trailer and the frequency of use when making this choice.

- Installation considerations: Think about the installation process. Will you install the outriggers yourself, or will you require professional assistance? The complexity of the installation process might influence your choice.

- Swing-out reach: The maximum outward reach of the outriggers determines how wide a platform they can create. Consider the widest equipment you plan to transport and choose outriggers with an adequate swing-out reach.

- Jack stands: Some outriggers incorporate jack stands for additional stability. These jacks can be helpful for leveling the trailer and fine-tuning the outrigger positioning.

How Can Proper Use and Maintenance of Outriggers on a Lowboy Trailer Prolong the Lifespan of Your Heavy Equipment and Reduce Transportation Cost?

- Minimizes strain: Outriggers provide a more stable platform during transport, reducing stress and strain on the frame and components of your heavy equipment. This can help prevent premature wear and tear, extending the overall lifespan of your valuable machinery.

- Faster loading and unloading: Outriggers can create a more stable and accessible platform for loading and unloading heavy equipment. This can improve efficiency and reduce the time it takes to complete a transport job.

- Minimized delays: Properly maintained outriggers are less likely to malfunction or break down during transport, reducing the risk of delays and keeping your operation running smoothly.

- Regular inspections: Conduct regular inspections of the outriggers to identify any signs of wear, damage, or loose connections. Address any issues promptly to prevent them from worsening and compromising safety.

- Lubrication: Lubricate moving parts of the outriggers according to the manufacturer’s recommendations. This reduces friction and wear, ensuring smooth operation and extending the lifespan of the outriggers.

- Cleaning: Clean the outriggers after each use, especially after operating in dusty or dirty conditions. This prevents dirt and debris buildup that could hinder proper operation or lead to corrosion.

- Proper storage: When not in use, store the outriggers properly to protect them from the elements and prevent damage.

What Are Some Common Challenges and Solutions When It Comes to Deploying Outriggers on a Lowboy Trailer During Heavy Equipment Transportation?

Despite their numerous advantages, deploying outriggers on lowboy trailers can present some challenges during heavy equipment transportation. Here’s some common issues and potential solutions to ensure safe and efficient use of outriggers:

Challenges:

- Limited space: In tight spaces or congested areas, fully extending outriggers might not be possible. This can limit the trailer’s stability, especially when dealing with very wide or heavy equipment.

- Uneven surfaces: Deploying outriggers on uneven terrain can be tricky. If the outriggers can’t establish a level and secure base, the trailer might be unstable, compromising safety.

- Time constraints: Extending and retracting outriggers, especially manual ones, can add time to the loading and unloading process. This can be a concern when working on tight schedules.

- Improper use: If not deployed or secured correctly, outriggers can fail to provide the intended stability, potentially leading to accidents or damage.

Solutions:

- Planning and foresight: When planning a transportation route, consider potential space limitations and identify areas where full outrigger extension might be difficult. Look for alternative solutions like using different routes or off-site staging areas with better space.

- Blocking and cribbing: For uneven surfaces, use wooden blocks or cribbing materials under the outrigger pads to create a level and stable base for the trailer. This ensures the outriggers function effectively.

- Proper training: Ensure your crew receives proper training on the safe deployment, use, and inspection of outriggers. This helps prevent user error and promotes safe working practices.

How Do Industry Experts Recommend Customizing Outriggers on a Lowboy Trailer to Meet Specific Trucking and Transportation Needs for Various Types of Heavy Equipment?

While there are standard outrigger options available for lowboy trailers, industry experts often recommend customizing them to address specific trucking and transportation needs for various types of heavy equipment. Here’s how customization can be beneficial:

- Weight capacity: Standard outriggers might have a weight capacity that only meets your minimum requirements. Upgrading the outrigger components to handle heavier equipment provides a safety buffer and future-proofs your trailer for potentially larger cargo.

- Reach and width: Outriggers come in various lengths to accommodate different equipment widths. For particularly wide equipment, custom outriggers can be built with an extended reach to create a wider support base for exceptional stability.

- Low-ground clearance equipment: For equipment with very low ground clearance, standard outriggers might not provide enough space for safe loading. Custom outriggers with a lower profile can be designed to address this challenge.

- Hydraulic options: While manual outriggers are cost-effective, hydraulic outriggers offer faster deployment and retraction, especially for frequently used trailers. Customizing allows you to choose the hydraulic system that best suits your needs.

- Lighting and warning systems: For increased visibility and safety, especially during night operations, custom outriggers can be integrated with lighting systems or warning signs to alert other drivers to the wide load.

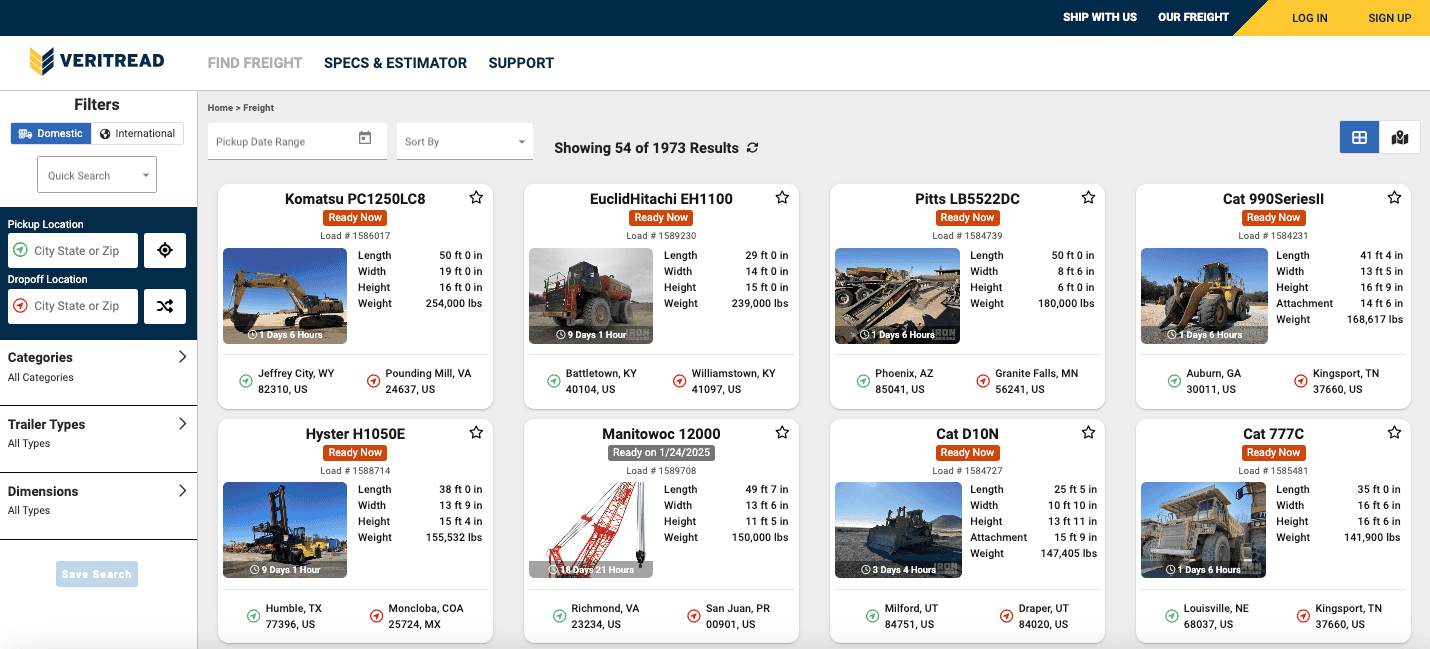

Why Join VeriTread As A Transport Provider?

VeriTread has 100’s of loads that you won’t find anywhere else with new loads listed every day. When you complete a profile on VeriTread, we learn detailed information about your equipment, your capabilities, and the areas you service. We combine this information with our patent pending freight matching technology to proactively find you the best paying freight available. VeriTread is reserved only for carriers, brokers, and forwarders, who are properly bonded, licensed, and insured which reduces overall risk as well as keeps rates at a fair and profitable level.

veritread products

Top Articles

Freight Types

recent posts

Basic Tips of Heavy Equipment Transport

Understanding Equipment Transport Services