Flatbed Trailer Transport

LIST YOUR FREIGHT

CONNECT WITH A CARRIER

SIT BACK & RELAX

Flatbed Trailer Transport - The Ultimate Guide

Tips, Tricks, and Things You Should Know.

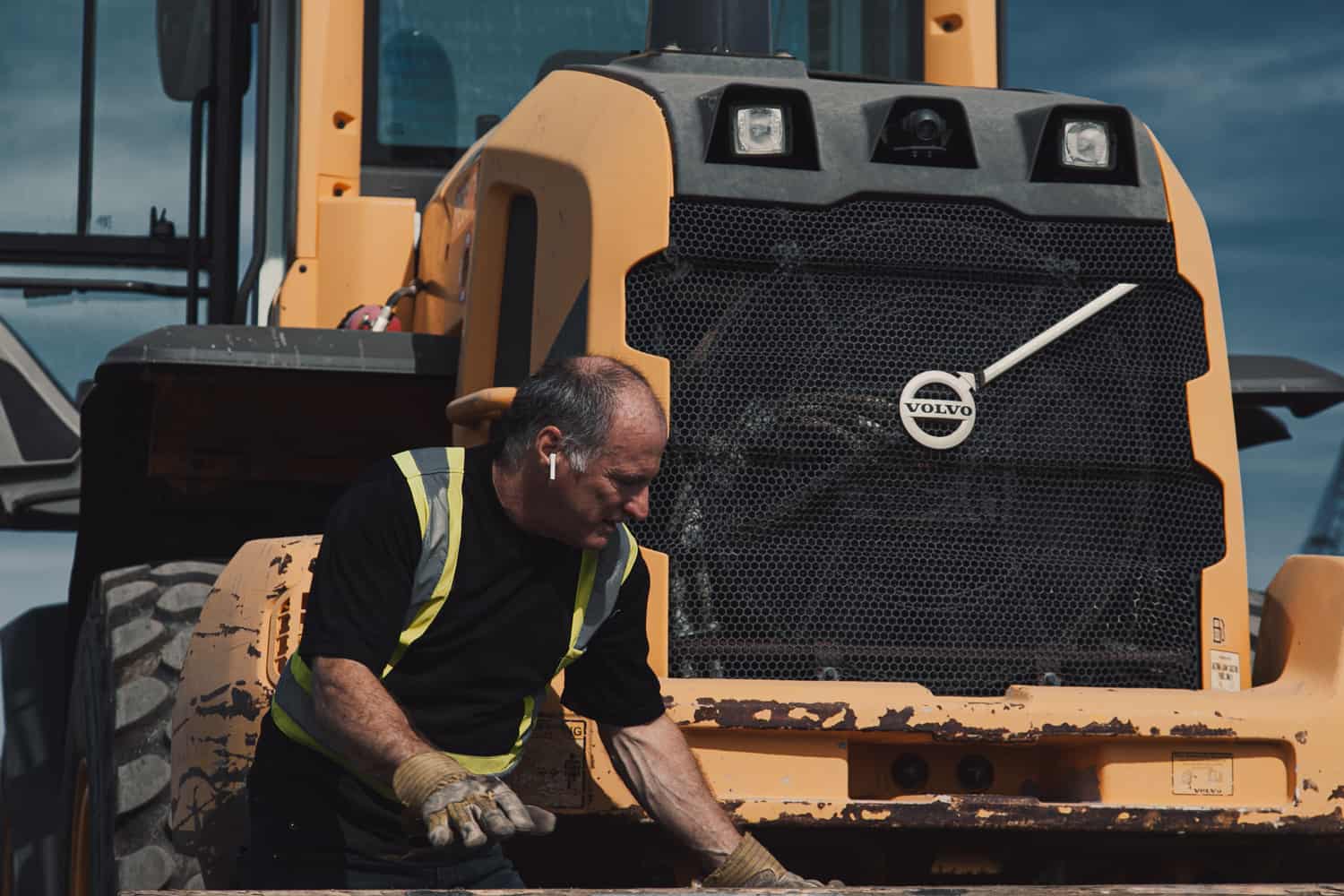

Flatbed trailers are popular, especially for hauling irregularly shaped cargo like pipe, steel, lumber, block, construction equipment or large vehicles which don't fit into the traditional dry van trailer (e.g., truck). Flatbed trailers may include several type of trailers like: lowboys, RGN, step decks, stretch double drop decks, extendable, Conestoga, and side kit trailers among other types. These trailers, also known as open deck, allow you to load and unload from either the front or back of the trailer without having to go through any doors on the other end. For example, they can be used in mining operations when dealing with excavators which don't fit easily onto car carriers because they're too large or have irregular shapes like buckets or hammers that need room for operation during transport.

Many individuals find that it is better to hire a professional to move their flatbed freight. This is especially true when moving loads over long distances, tricky routes, and through populated areas. It can be difficult and time-consuming to find the right transport provider to handle your load. Luckily, VeriTread is here for you! Our service connects shippers with qualified transport companies around the country who have extensive experience in transporting flatbed freight. Still, it’s always best to know everything about the process, should any surprises arise. We have prepared a fundamental guide for flatbed transport. Let’s dive into what it takes to safely and legally transport a flatbed load from one place to another.

Preparing A Flatbed Trailer For Transport

Loading & Securing Flatbed Trailers Safely

1) Using the right chains. A chain has a working load limit of 1/3 of the chain breaking strength. Understanding the weight capacity of each chain can get complicated because it depends on the diameter and the grade of the chain. Do your research if you are unsure.

2) Inspect chains for wear, drag marks, or broken links.

3) Connect at least one (1) chain from four (4) points of the equipment, usually to the axle which is considered to be more secure than the designated tie-down point provided by the manufacturer. Be sure to cross the chains. If you are loading equipment that has a bucket or backhoe, it’s best to run another chain over that object to prevent swinging or movement that could be a safety hazard. The chains should be attached to a D-ring or fed through the inside of the stake pocket and brought up on the outside for the stake pocket hooked to the top of the stake pocket. This should prevent the chain from coming detached if the chain loosens. Never run the chain on the outside of the rub rail. Position the chains so that the front chains pull forward and the rear chains pull backward and use a chain ratchet to secure the load.

1) When using straps, you must first make sure you are using the right straps with the proper weight limits. This is referred to as the working load limit which means the amount of weight each strap will support. The Working Load Limit is 1/3 of the breaking strength of the straps. For example, if the strap breaking strength is 10,000 lbs, the Working Load Limit is about 3,333 lbs.

2) Inspect straps to be sure there are no frays or cuts that could weaken the straps.

3) When securing supplies, straps should be placed every 10 feet. If the load is less than 10 feet long, two (2) straps are required.

If you are transporting machinery make sure all equipment attachments, work tools, and other accessory equipment must be lowered and secured before transportation. Retract booms and buckets and secure them in place. Secure equipment components (lock all doors, covers, tailgates, and articulation points). Also, make sure the machine transmission is immobilized and brakes are locked. For additional protection to your equipment, you may choose to cover it with a tarp or wrap it with shrink wrap. This protects the equipment from dirt, debris, and moisture on the roadways. For equipment with a smokestack, be sure to cover it so debris cannot enter. Use ample & appropriate securing devices (chains, binders, straps, & anchors). Choose appropriate attachment points on the machine and trailer. Once the load is secured, check everything a second time. It can be helpful to have a safety check system in place where multiple people check the load, instead of relying on a single person.

Check out a good securement video from Dirt Perfect. It covers tips. tricks, do's & don'ts for equipment greater than 10,001 lbs.

Transporting Flatbed Freight

Heavy loads can be very dangerous in rush hour traffic in big cities. Take time before your trip and map out a route (and time) that avoids areas of construction or heavy congestion on the roadways, you'll thank yourself later! Try to avoid toll roads, low-hanging bridges, or any other interruptions or delays that could slow transportation. The best routes have the least amount of bridges, turns, starts, stops, and difficult terrain.

You also need to be sure that the roads along your route can handle the weight, height, and width of the load. It is very dangerous to assume that all roads can handle the weight of a heavy load. If the area is unfamiliar, then we strongly suggest you drive the route in a smaller vehicle first to identify areas of concern.

Heavy load securement requires check-ins and inspections while on the road, especially when traveling long distances. Walk around the trailer every time you stop for gas, food or a rest break and look for any indicators that the load is shifting, restraints are being damaged, etc. Have extra restraints with you so you can replace or reinforce those you’re already using if necessary.Industry safety standards recommend the following as inspection benchmarks while heavy cargo is en route:

- Once during the first 50 miles of transport.

- Once every 150 miles or once every 3 hours — whichever comes first for long-distance hauls.

- At every change of duty or change of driver station. Have the new driver run a full inspection, then document that inspection in a transport log.

Safely Unloading A Flatbed Trailer

Before unloading, take the time to review and clear the designated unloading area in the receiving yard. Just as you pay attention to this during the loading phase, wet and muddy ramps, cluttered docks, and uneven unloading ground make this part of the operation much harder than necessary. Line the ramps up with the rear of the trailer bed as methodically as possible, taking time to match joints and eliminate any gaps between the trailer and the ramp or dock. Once the machinery begins backing up, there will be no time to reposition.

With everything in place, conduct a final condition survey. Look over the equipment’s tires and hitches to ensure their health. Review roles with personnel, appointing a spotter and an equipment operator just like during the loading process and before you begin breaking down the chain tie points. You’ll also want to do a brief survey on the condition of the tie-downs themselves before their release. It is highly unsafe to undo straps and chains if the load has shifted, even minutely. If this is the case after performing a walk-through, you and the operators will have to draw up a custom unloading plan.