What is a Lowboy Trailer?

If you are moving any form of large goods, you need to use the right trailer. Trailers are not a one size fits all unit. At any one moment, there are numerous types of trailers navigating roads all over the world. Different trailer types are built to fulfill different purposes. There is one type of trailer you have likely seen hauling construction equipment and industrial machinery–the lowboy trailer. It is one of the most versatile. Here’s a quick guide on lowboy trailers and the most important things you need to know.

What is a Lowboy Trailer?

A lowboy trailer is a semi-trailer with a drop-deck. Its deck has two drops–one immediately behind the gooseneck and the other just before the wheels. That means the tail end of the lowboy trailer sits above the well but remains lower than its front. This is why lowboy trailers are also referred to as double drops, low-beds, low loaders, or floaters depending on where in the world you are.

The maximum dimensions of a lowboy trailer may vary slightly as follows:

● Maximum well length – 24 feet to 29.6 feet

● Maximum well height – 18 inches to 24 inches

● Maximum legal width – 8.5 feet

● Maximum legal freight height – 11.5 feet to 12 feet

● Maximum legal overall load height – 14 feet

A two-axle lowboy trailer’s maximum weight is 40,000 pounds but can be increased to as much as 80,000 pounds depending on the number of axles. A 25-ton lowboy trailer can ship over 50,000 pounds while a 35-ton trailer can move more than 70,000 pounds. The most common truck and lowboy trailer configuration will have a tri-axle semi-trailer truck.

Why Use a Lowboy Trailer Over Other Trailer Types?

Lowboy trailers are preferred for moving bulldozers, excavators, backhoe loaders, and other outsized equipment or cargo. Here is why.

Stability

The low-lying deck of lowboy trailers means they have a low center of gravity. They are more stable than other trailer types when moving heavy or large cargo.

Safety

Lowboy trailers are designed to carry heavy and large loads that would otherwise be dangerous to haul with other trailer types. Large, heavy cargo can be loaded and offloaded with relative ease.

Versatile

Lowboy trailers can carry not just heavy cargo but over-width loads. Heavy industrial and construction equipment is often unusually wide. A trucking company that handles a wide range of cargo does not need several different types of trailers. Lowboy trailers can handle almost any type of cargo as long as it falls within their carrying capacity.

Compliance with Height & Weight Restrictions

Some countries, regions, and areas have laws that outline the height of cargo that can be moved by road. Lowboy trailers allow trucking companies to transport large cargo without breaking applicable laws. Loads may be as tall as 14 feet. The lowboy trailer’s design allows it to sit unusually close to the ground when compared to regular flatbed trailers. This makes it best-suited for transporting items whose height would otherwise exceed standard height limits for road freight if they were to be moved via other trailer types.

Certain states/providences have regulated weight requirements. They must comply with the federal bridge formula (disbursement of weight) as well as permissible travel times combined with length, width, height, and weight restrictions in able to be transported over the interstates, highways, and roads within each jurisdiction.

Different Types of Lowboy Trailers

There are different types of lowboy trailers. The most widely-used categorization is based on how the gooseneck is attached to the trailer.

Fixed Neck Lowboy

A fixed neck lowboy is fitted to the trailer. This makes it a lightweight alternative. The fixed style implies it is harder to load from the front of the trailer.

Fixed Gooseneck Lowboy

Fixed gooseneck lowboys (FGLs) have drop decks that make them easy to load from both the back and the front. The gooseneck itself is adjustable and, once reattached, ensures the cargo on the trailer stays in position.

Removable Gooseneck Lowboy (RGN)

Removable gooseneck lowboys (RGNs) are the ultimate heavy duty haulers. RGNs can have as many as 20 axles giving them the power to carry as much as 150,000 pounds of cargo. They come in handy when the cargo needs to be pulled, pushed, rolled, or driven onto the trailer bed. You may also load bulkier, heavier items from above if need be. RGNs are also known as detachable gooseneck lowboys.

There are two types of RGNs.

Hydraulic RGNs

Hydraulic RGNs are the most common lowboy trailers. They use hydraulic cylinders that perform trailer detachment and height adjustment with ease. Trailer operators can retain a low center of gravity in instances where loads are unusually tall.

The hydraulic systems add significant weight to hydraulic RGN trailers thus lowering the overall carrying capacity. They require more frequent and elaborate maintenance than mechanical RGNs. Hydraulic RGNs are expensive as well.

Mechanical RGNs

Mechanical RGNs use a manual or spring mechanism to lift the ramp. Most people opt for hydraulic RGNs but there are situations where mechanical RGNs are the better option. For example, a mechanical RGN will be your best alternative in long-distance trucking where the load is expected to remain on the trailer for several days. They are also preferred where unloading must be done on hard, smooth surfaces. Mechanical RGNs are harder to operate, but also have lighter weight and less maintenance overall.

Things to Pay Attention to When Buying or Hiring a Lowboy Trailer

Buying a lowboy trailer is a substantial investment. It is important that you get it right the first time. The type of lowboy trailer you buy is certainly important but there are other factors to pay attention to. If you are shopping for a lowboy trailer, you need to consider the following five factors in order to make the right decision.

Material

Lowboy trailers transport heavy cargo. They should be made from metal that can withstand continuous pressure and friction from such loads. Usually, lowboy trailers are made from aluminum or high-strength steel. High-strength steel has greater yield strength and costs less. Aluminum resists rust and is lighter weight. If you purchase an aluminum lowboy trailer, the load should not exceed 50 tons.

Suspension Options

The most common suspension options for a lowboy trailer are the rigid, mechanical, air ride, and single point systems. Choice of suspension will largely depend on budget, weight capacity, transportation speed.

Rigid Suspension

Rigid suspension systems are mainly used for heavy-duty lowboy trailers and most suitable for low speed hauling. The movement of a wheel depends on the movement of other wheels. Rigid suspensions are easy to maintain and install. They are inexpensive too. By improving wheel alignment and stability, they extend trailer tires service life.

Mechanical Suspension

A mechanical suspension system uses a series of reaction arms to keep axles horizontal. It is stable with constant load distribution. Mechanical suspensions are most appropriate for heavy-duty trailers. They are reliable, inexpensive, and easy to maintain.

Air Ride Suspension

An air ride suspension is the lightest suspension used on lowboy trailers. It has good stability and greater flexibility than other trailer options. The trailer’s spring adjusts in accordance with the cargo’s weight. It has longer tire life and better fuel economy. The lower vibration reduces the trailer’s wear and tear. Air ride suspensions are a costly option.

Single Point Suspension

A single point suspension system is most useful where the trailer needs to carry unusually heavy cargo. Such cargo could be as much as 100 tons. It has a robust damping effect that lowers the amount of vibration on the trailer thus decreasing the lowboy’s wear and tear. As you would expect, this suspension system is fairly expensive.

Tires

Lowboy trailers may either use tube tires or tubeless tires. The tire you choose depends on your intended use of the trailer.

Tube Tires

Tube tires are more stable on rough terrain. They are pressurized and can thus support heavy loads. Tube tires can be repaired relatively simply and cost-effectively. They are however more prone to blowouts if they are pierced. Tube tires have a comparatively short service life.

Tubeless Tires

Tubeless tires are more resilient and will not readily blow out when pierced. Instead, they experience slow discharge of pressurized air. They have good wear resistance and a relatively long service life which makes them ideal for long distance trucking.

On the downside, tubeless tires are unpressurized so cannot handle heavy loads as well as tube tires nor are they suitable for rough terrains. Tubeless tires are tedious and costly to repair.

Carrying Capacity

Lowboy trailers are categorized by tonnage. The two most common tonnage options are the 50,000-pound (25-ton) trailer and the 70,000-pound (35-ton) trailer. A lowboy trailer’s actual carrying capacity is determined by its net carrying capacity and not the weight of its load. So if a trailer weighs 30,000 pounds and has a 50,000-pound carrying capacity then it can only carry 20,000 pounds.

Thus, the actual weight of the trailer itself should be taken into consideration when purchasing it. Determine the maximum weight of the cargo you intend to carry then calculate whether the trailer’s weight allows you to do so.

Budget

Price should never be the primary consideration for choosing a particular lowboy trailer but there is no question it is an important one. You have a finite budget and ultimately, can only buy what you can afford. The good thing is there are bound to be multiple lowboy trailer alternatives within your target price range.

Conclusion

Lowboy trailers are built to transport the heaviest, bulkiest loads. A lowboy trailer can get your large oversize equipment, machinery, or cargo to your project, job site, or other destination safely, legally, and in good time. The dimensions, number of axles, and number of beams vary across lowboy trailers. Your best choice of lowboy trailer will depend on multiple factors such as intended use, size, and weight of expected loads, maintenance costs, future needs, and price.

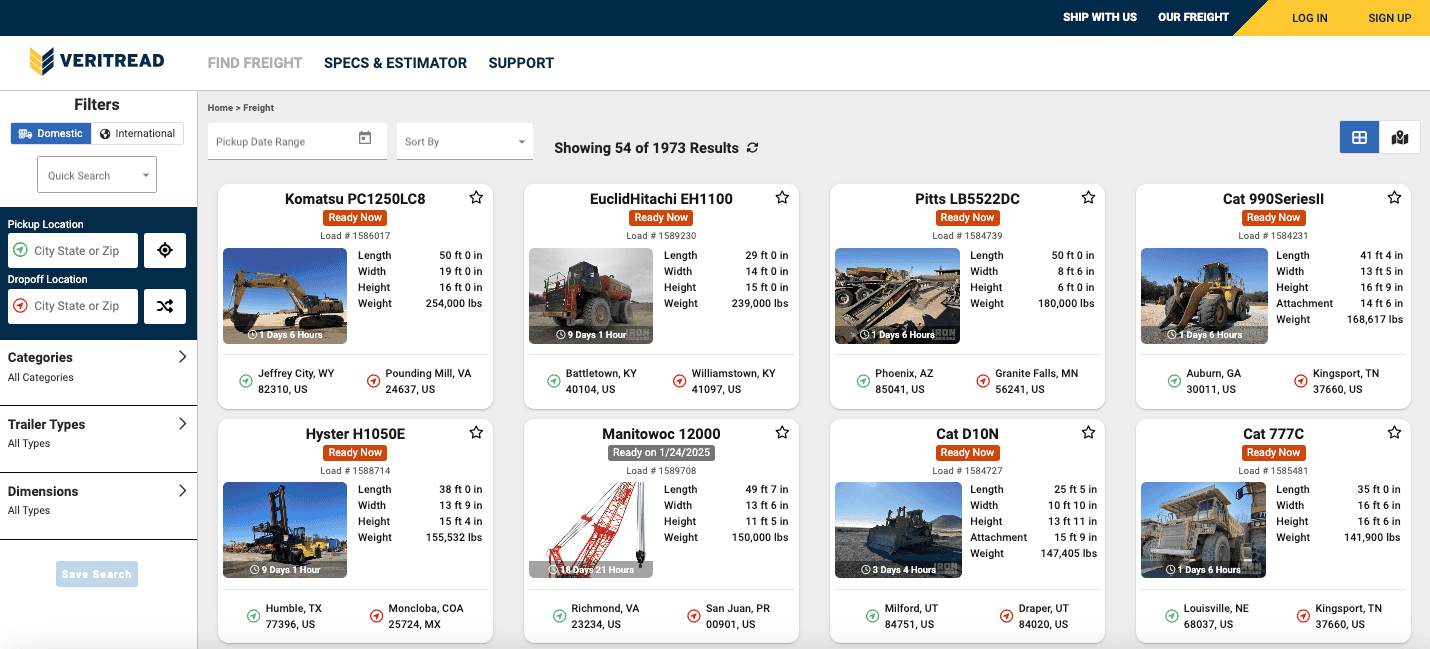

About VeriTread

VeriTread is your go to solution for Lowboy transport. We can have your LTL freight delivered to any destination in North America in a safe and timely manner. We are experts at handling paperwork, selecting the right trailers and drivers, and charting the most efficient routes.

VeriTread makes it easy to get reliable freight quotes from the experts in equipment transport. VeriTread moves thousands of machines every year and can quickly generate a reliable quote on the go. Our extensive specs and dimensions database of 60,000+ items, ensures you spend less time researching and more time putting your equipment to work. The VeriTread Shipper quote process is the simplest way to transport your machines. Follow these easy steps and you will receive a quote in under one minute:

• Enter a Manufacturer & Model

• Verify or Edit Your Machine Dimensions

• Enter Pickup & Drop Off Locations

• Your Quote is Ready!

Getting started with VeriTread is easy. You can visit our contact form or call (800) 880-0468 or (863) 226-0903 for international calls.

veritread products

Top Articles

Freight Types

recent posts

Basic Tips of Heavy Equipment Transport

Understanding Equipment Transport Services